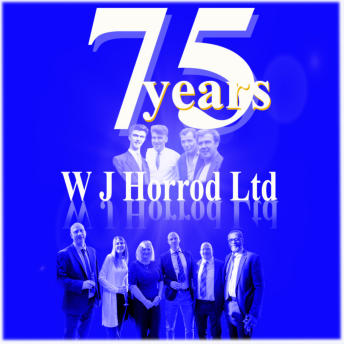

A family business established in 1950

A family endeavour

Origins

Terry Horrod, (right) receiving an

award for 50 years of service to the

industry. At the MAC AGM in 2009 from

Chairman Keith Collins.

The present, and the future!

Below: Terry Snr at his desk;

circa early 2000s.

In keeping with our long tradition as a family business, there are now two generations working side by side.

The reputation of our company is extremely important to us, safety, efficiency, and engineering excellence.

Left:

William (Bill) Horrod

Alec Horrod

Terry Horrod

Right:

Kenny

Bill H.

‘Packy’ Padwick

Terry H.

Left to Right:

•

Thomas Horrod

•

Toni Horrod

•

Kim Wilkins

•

Terry Horrod Jnr

•

Terry Horrod

•

Donavan Watt

From meagre beginnings in 1948, as simply a repair service, Horrod's built itself into the

market leader in the manufacture of asphalt and bitumen equipment, civil engineering, and

highways maintenance plant.

Over the years the company has diversified, building trucks and trollies (manual handling

equipment) and even Hot Boxes, used to store and transport tarmacadam to the nation’s

roadways.

The company was incorporated in January 1961 as a limited company.

Alex and William (Bill) named the company W J Horrod Ltd in tribute to their father,

William John Horrod, who Bill was named after. They employed half-brother Henry James,

who was affectionately known as Packy, and their youngest brother Terry.

Family tragedies in the 1970s saw the loss of first Alex, and then Bill, leaving little brother

Terry to take over, with little to no experience of running a business.

Beside him was daughter Kim, and a year later, his only son Terry Jnr joined the

company, although he had in fact been learning his trade most of his early adult life.

Terry Horrod Snr held himself to a very high standard, thus the company he over saw

was designed and built with the simple philosophy; quality, and safety first.

During this early period, it was always difficult to encourage stubborn roofers, set in their

ways, to understand that some of their practises on site were dangerous.

It was an uphill battle, but nonetheless he persisted, responding each time the industry posed

a question for equipment that would pass muster in an increasingly safety conscious industry;

safety trays, safety buckets, thermostat-controlled bitumen boilers (that actually worked, as

under testing earlier thermostat-controlled boilers, imported from overseas, allowed the

temperature to rise well above the accepted limit for bitumen in the UK.) Horrod’s worked

with Chiltern Services to provide a unit that did exactly as safety and material integrity

demanded - shutting down the burners once the bitumen reached its optimal level.

He also advised HSE on good practices, and assisted in some of their accident

investigations. Terry Horrod wanted rid of ‘cowboy’ methods!

He pioneered safer practices and introduced user training to help better understand

the equipment and the materials used in the trade. His passing in August 2009 was mourned

by many in the industry.

A family business established in 1950

A family endeavour

Origins

The present, and the future!

In keeping with our long tradition as a family business, there are now two generations working side by side.

The reputation of our company is extremely important to us, safety, efficiency, and engineering excellence.

From meagre beginnings in 1948, as simply a repair service, Horrod's built itself into the

market leader in the manufacture of asphalt and bitumen equipment, civil engineering, and

highways maintenance plant.

Over the years the company has diversified, building trucks and trollies (manual handling

equipment) and even Hot Boxes, used to store and transport tarmacadam to the nation’s

roadways.

The company was incorporated in January 1961 as a limited company.

Alex and William (Bill) named the company W J Horrod Ltd in tribute to their father,

William John Horrod, who Bill was named after. They employed half-brother Henry James,

who was affectionately known as Packy, and their youngest brother Terry.

Family tragedies in the 1970s saw the loss of first Alex, and then Bill, leaving little brother

Terry to take over, with little to no experience of running a business.

Beside him was daughter Kim, and a year later, his only son Terry Jnr joined the

company, although he had in fact been learning his trade most of his early adult life.

Terry Horrod Snr held himself to a very high standard, thus the company he over saw

was designed and built with the simple philosophy; quality, and safety first.

During this early period, it was always difficult to encourage stubborn roofers, set in their

ways, to understand that some of their practises on site were dangerous.

It was an uphill battle, but nonetheless he persisted, responding each time the industry posed

a question for equipment that would pass muster in an increasingly safety conscious industry;

safety trays, safety buckets, thermostat-controlled bitumen boilers (that actually worked, as

under testing earlier thermostat-controlled boilers, imported from overseas, allowed the

temperature to rise well above the accepted limit for bitumen in the UK.) Horrod’s worked

with Chiltern Services to provide a unit that did exactly as safety and material integrity

demanded - shutting down the burners once the bitumen reached its optimal level.

He also advised HSE on good practices, and assisted in some of their accident

investigations. Terry Horrod wanted rid of ‘cowboy’ methods!

He pioneered safer practices and introduced user training to help better understand

the equipment and the materials used in the trade. His passing in August 2009 was mourned

by many in the industry.