A family business established in 1950

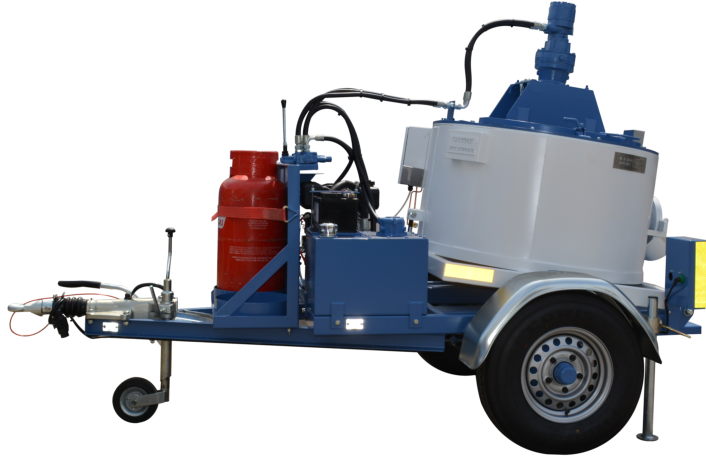

Swiftmelt

Thermostat Controlled Asphalt Mixer

Ideal for use with:

The SwiftMelt

•

SwiftMelt thermostat controlled Mastic Asphalt Mixer - taken from an original

design and adapted originally for use with ‘Pacopatch, a polymer modified mastic

asphalt permanent reinstatement system primarily designed for use around

manholes and other street ironworks.’ (Pure Asphalt Co Ltd, now Iko Pacopatch.)

•

The vertically stirred design unlike, conventional horizontally stirred machines,

does not lift the material away from the heat.

•

The Whirlpools unique vertical stirrer design pushes the material over the

stirrers thus spending less time away from the heat.

•

The inverted pan provides a greater heating surface area and combined, these

two features give an overall quicker heating time and use less LPG Propane gas.

•

A Thermostatically controlled flame failure device - pilot protected main burner

system heats the material to the required temperature, meaning it is used only

when needed, making it ecologically friendly and preventing any material

degradation.

Reinstatement in action

1000kg roll-on trailer mounted SwiftMelt

500kg model roll-on chassis SwiftMelt

These images are reference purpose only

our new design above!

Introducing our latest addition! SwiftMelt 250kg

Our smallest Thermostatically controlled mastic asphalt mixer

For comparison

500kg

250kg

Horrod’s will always cater for our customers needs where it’s possible.

Our newest creation is smaller by size as well as capacity!

A family business established in 1950

Swiftmelt

Thermostat Controlled Asphalt Mixer

Ideal for use with:

The SwiftMelt

•

SwiftMelt thermostat controlled Mastic Asphalt Mixer - taken from an original

design and adapted originally for use with ‘Pacopatch, a polymer modified

mastic asphalt permanent reinstatement system primarily designed for use

around manholes and other street ironworks.’ (Pure Asphalt Co Ltd, now Iko

Pacopatch.)

•

The vertically stirred design unlike, conventional horizontally stirred machines,

does not lift the material away from the heat.

•

The Whirlpools unique vertical stirrer design pushes the material over the

stirrers thus spending less time away from the heat.

•

The inverted pan provides a greater heating surface area and combined, these

two features give an overall quicker heating time and use less LPG Propane gas.

•

A Thermostatically controlled flame failure device - pilot protected main burner

system heats the material to the required temperature, meaning it is used only

when needed, making it ecologically friendly and preventing any material

degradation.